STEIN 400

For heavy itemsEfficient for heavy workpieces

Easy transport with STEIN SOFTMOVE

The benefits of STEIN 400

- extremely quiet

- for weights up to 80 kg

- pallet sizes from 240 x 240 mm (freely scalable)

- speeds up to 30 m/min.

- large selection of components (transfer unit, centering devices…)

- minimal wear and tear due to roller cassettes

- flexible transport

At STEIN, your employees take centre stage

quiet

The gentle drive of the motors dramatically reduces noise. Pallets do not bump against each other. Belts do not wear through.

convenient

Free access to closed internal spaces in the system allows installation technicians to work in a relaxed – and more successful – way. This can reduce the downtime.

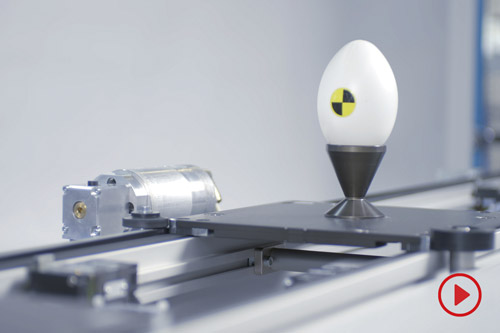

informative

The product communicates with the operator. This supports the working process directly, especially since this feature is also available as a navigator.

fast

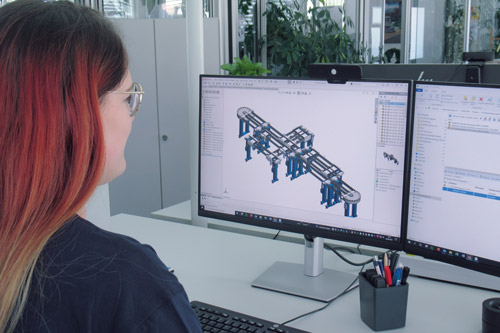

Individual orders and entire production schedules can be created with just a few mouse clicks. This allows our customers to configure their processes very easily without having to do any programming.

ideal

Everyone is unique and has their own ideal working height. With STEIN, operators are free to choose the height, allowing them to stay relaxed to provide the best performance. Your employees and customers will certainly thank you.

reliably

The longevity of the transfer line as well as the professional consultation is repeatedly confirmed by our customers. Continuous improvement is firmly anchored in our daily work.

STEIN 300

The STEIN 300 has a fixed place in over 3,900 assembly halls. With a vast range of customers and in a wide variety of configurations.

From a simple circuit right through to ERP connection or traceability functionality, each installation is custom-made for our customers using a standard toolkit.

STEIN 300e

STEIN promotes the trend towards electrification with the STEIN 300e, which is based on the STEIN 300. Instead of pneumatics, the stoppers, transfer units or centering devices are controlled via electric drives. This is particularly a big advantage for cleanroom applications. As a side benefit, your production is more environmentally friendly.

STEIN Control

Especially in times of Industry 4.0 vertical integration is possible by the STEIN CONTROL.