One Piece Flow

For consistent quality and quantityOne Piece Flow as part of LEAN Management

STEIN Components

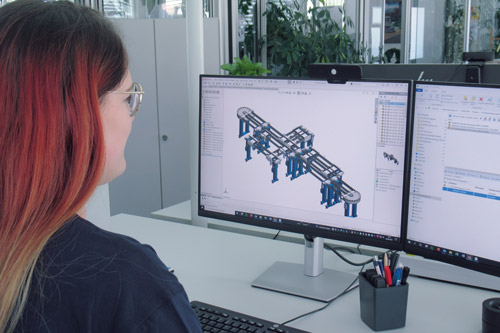

STEIN 300 with individual components is the basis for successful production. To allow customers to go their own way when realising their installations, all components and corresponding data are available in the ‘toolkit’. Plant designers and engineers can use them to create custom solutions with all the possibilities of STEIN technology.

STEIN assembled

STEIN 300 assembled is a good choice for anyone wanting to order an installed system rather than individual components. Savvy planners can configure a system themselves, whilst STEIN assembles the individual components and delivers a system that is virtually ready to use. Controlling the system with software and hardware is left to the customer.

STEIN CONTROL

The complete system for central management and control is quick to get up and running. With the STEIN 300 assembled and equipped with the STEIN LOGISTIC system controller, the process can be managed and monitored. Individual orders and entire production schedules can be created and processes can be configured at the click of a mouse.

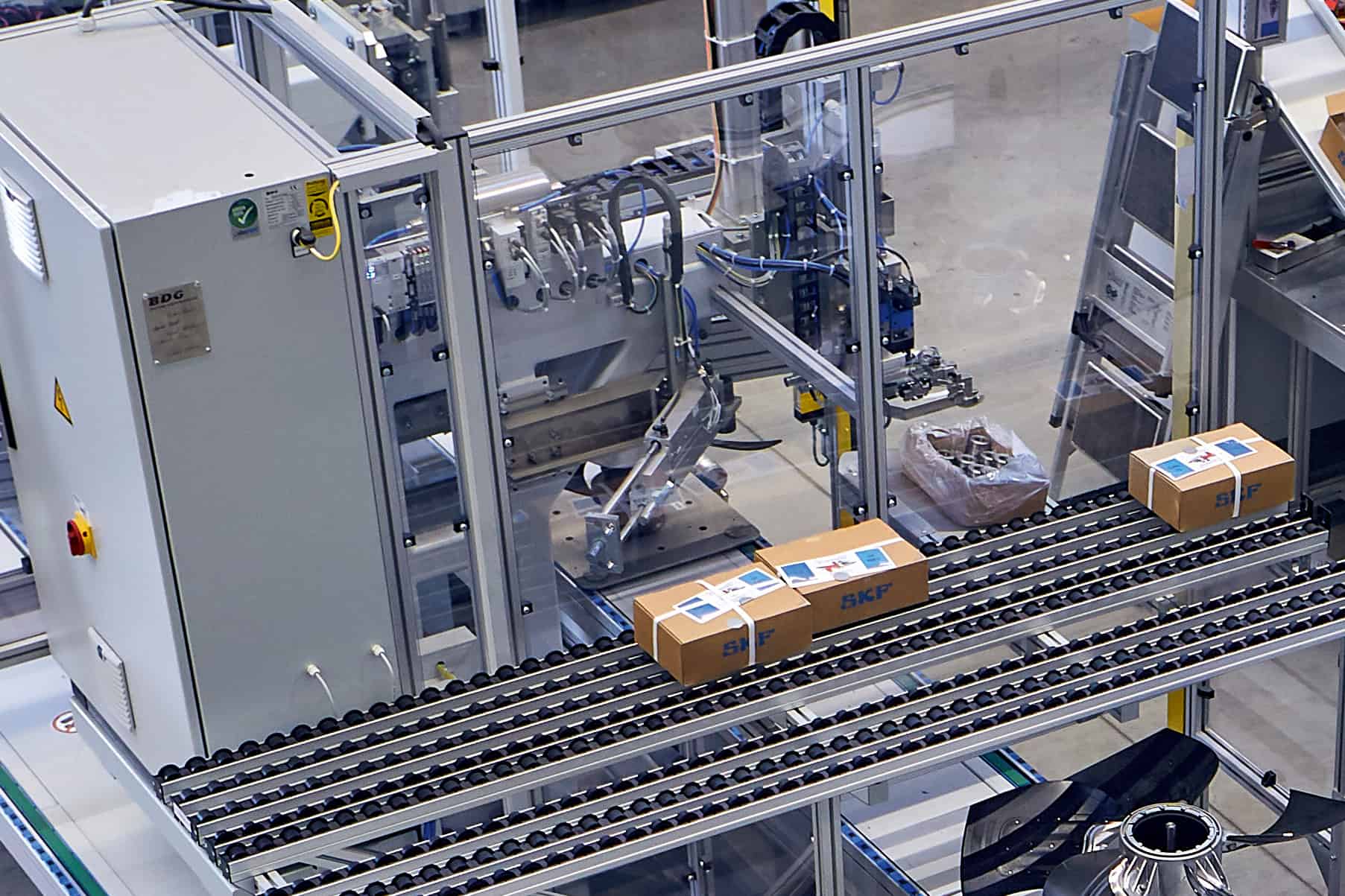

The method known as “STEIN LEAN” is used where material is to be continuously processed from the beginning of a production process to the end in a single flow, to the extent possible. This also makes it possible to react flexibly, in the event of errors, and to interrupt the production process quickly so that no further bad parts are produced.

More secure, faster and more reliable transport through the production line

STEIN LEAN & the right modules

Of course, basically all parts of the proven STEIN 300 can be used in a LEAN PRODUCTION-variant of the system. The most common components, which meet the basic needs of LEAN PRODUCTION, are however:

- manual roller track or conveyor with drive

- manual Workstation

- roller table

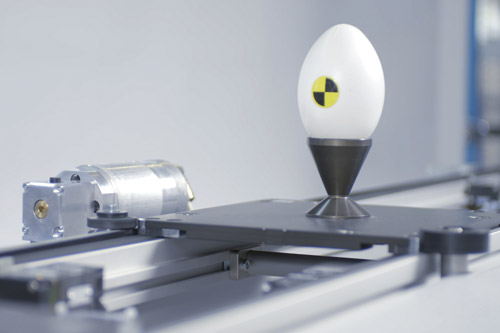

- centering unit

The main advantages of One Piece Flow for your production

Better quality short term

High flexibility in regards to variants

High flexibility in regards to associates because not all work stations need to be staffed

Better pre-conditions for Mass Customizing and versatile production systems

Less inventory resulting in smaller space and capital demand due to batch size 1

Shorter delivery times because there is no need to wait to have a full batch of a certain variant

Automation and logistics for the industry of tomorrow

- Noise reduction by SOFTMOVE up to 75%

- Energy savings using SOFTMOVE up to 80%

- Flexibility using height adjustable manual workstations – 100%

STEIN 300

In over 3,900 assembly facilities STEIN 300 has its firm place in production. At a variety of customers and in various configurations

STEIN 300e

Instead of pneumatics, the stoppers, transfer units and centering units are controlled with electrical drives in STEIN 300e.

STEIN 400

STEIN Control

Softmove

STEIN LEAN

Modular system

Downloads

+49 7728 64485 - 0

Johann-Liesenberger-Straße 7

78078 Niedereschach

Germany

Contact

Write to us, because together we can achieve a lot.